Taking the right decision with confidence

Our certifications are proof of ultimate precision and quality, efficient management and thoughtful use of resources. Nonetheless, we are determined to enhance our economic performance even further.

The Wehrle quality management in brief:

- Zero error philosophy

- SPC production

- Batch tracing

- IMDS, ROHS, REACH, BOMcheck

- 8D report management

Process optimisation – nothing new to us

A familiar and trusting works atmosphere has always made sure that everybody, working for WEHRLE makes their daily active contribution when it comes to improving the quality of our products, processes and services. Today, our ability for steady further development manifests itself in highly developed systems for process control, modern quality management and high environmental standards.

The systematic Wehrle energy management is ISO 50001 certified – a quantum leap in efficiency we pass on to our customers

Quality begins in the mind

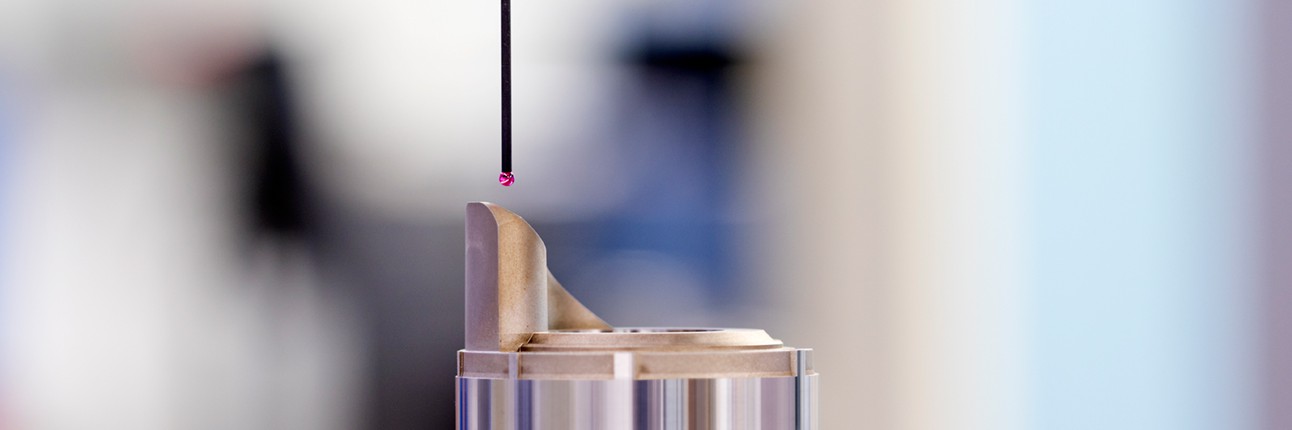

”Acting instead of reacting”: this could be seen as the principle underlying our forward-looking and anticipative maintenance. Wehrle safeguards stable processes by generating and strictly observing maintenance and service schedules. First sampling in our own Technical Centre gives us the opportunity to use only those moulds and tools in production which have been approved for series manufacture. Technical injection trials and related material tests are also among the work and services which can be realised at short notice. A computer-assisted system for quality assurance (CAQ) accompanies every product from the planning stage to final inspection. Processes can be monitored both with respect to parts and to customers – important preconditions to account for individual needs and requirements. We use optical and tactile measuring machines to permanently monitor all product features and properties. Different methods for gearing measurements are also in use – the two-flank rolling test, among others.

Our “Quality Assurance Manual” specifies all the actions involved in quality management. This allows us to avoid misunderstandings and delays with the help of clearly defined responsibilities

Deep-rooted performance

The well-regulated control of inspection, measuring and test equipment and test methods using the latest technologies is everyday practice at Wehrle. As a company which has for many decades internalised quality and responsibility, our steering acti ons go even further: everybody at Wehrle ’s – from trainee to managing director – regularly uses the wide-ranging programmes for training and advanced training. We work together in a well-coordinated way on our processes which we align along clearly formulated targets. We take decisions based on measurable data and closely follow the principles of a customer-focused organisation.

- DIN EN ISO 9001 certification

- DIN EN ISO 14001 certification

- Energy management system certified under DIN EN ISO 50001

- Occupational Health and Safety management system certified under BS OHSAS 18001

- Approved by the Physical Technical Federal Institute (PTB) under EU Directive 2004/22/EG Schedule D (Water and Heat)